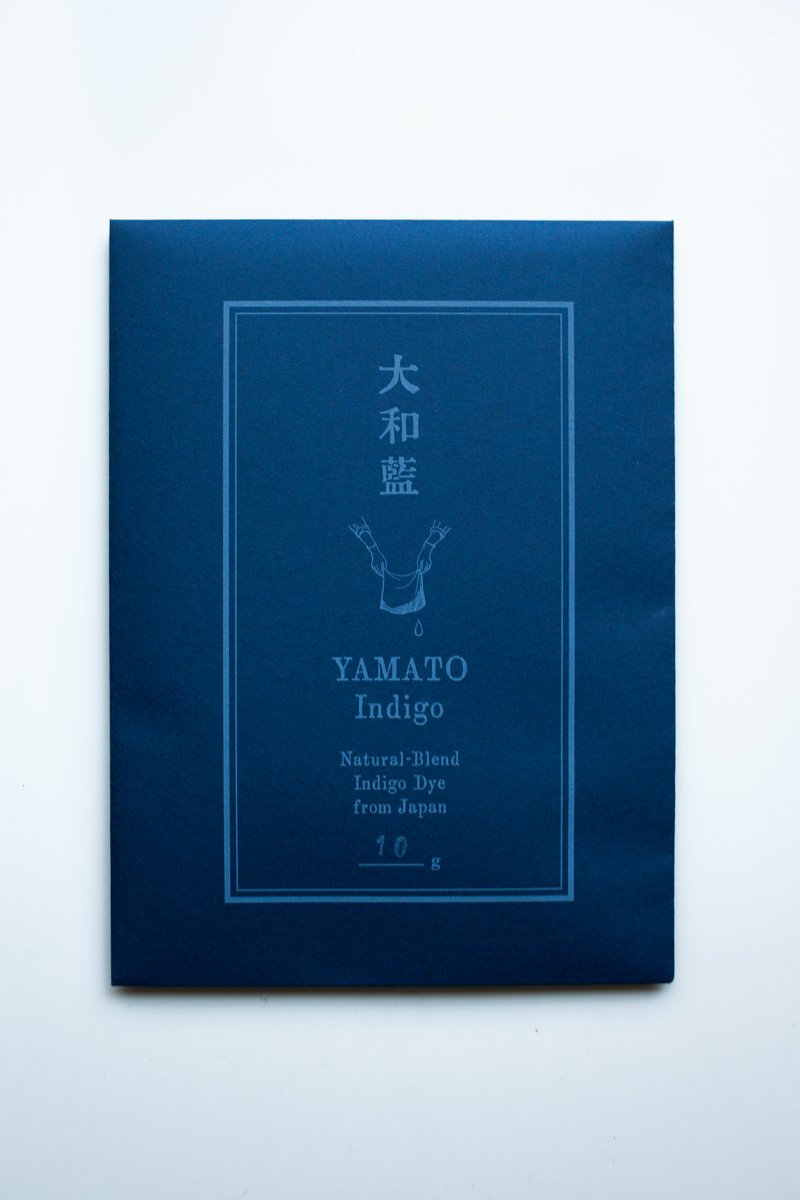

Yamato Indigo Dyestuff

Yamato Indigo is a Japanese natural-blend indigo powder dye. Easy to use, Yamato Indigo only needs water; no heating or fermentation is necessary. It dyes natural materials, such as cotton, linen, silk, leather, wood, and washi paper, into a vibrant, beautiful “Japan Blue.”

Yamato Indigo comes in the form of a powder consisting of extracts from indigo plants, synthetic indigo, alkaline agent, and reducing agent. By mixing it with water, it instantly becomes ready to dip and use as a dye.

This indigo dye is the best choice for absolute beginners, workshop teachers, and professional dyers.

10g pack makes 2 to 3 liter vat

Good to dye small items such as napkins and bandanas.

30g pack makes 6 to 10 liter vat

Good to dye medium items such as T-shirts, canvas totes and pillow cases.

*1 liter = 1.05 quart

available in 10g or 30g

Directions are included in the dye packet

Yamato Indigo is a Japanese natural-blend indigo powder dye. Easy to use, Yamato Indigo only needs water; no heating or fermentation is necessary. It dyes natural materials, such as cotton, linen, silk, leather, wood, and washi paper, into a vibrant, beautiful “Japan Blue.”

Yamato Indigo comes in the form of a powder consisting of extracts from indigo plants, synthetic indigo, alkaline agent, and reducing agent. By mixing it with water, it instantly becomes ready to dip and use as a dye.

This indigo dye is the best choice for absolute beginners, workshop teachers, and professional dyers.

10g pack makes 2 to 3 liter vat

Good to dye small items such as napkins and bandanas.

30g pack makes 6 to 10 liter vat

Good to dye medium items such as T-shirts, canvas totes and pillow cases.

*1 liter = 1.05 quart

available in 10g or 30g

Directions are included in the dye packet

Yamato Indigo is a Japanese natural-blend indigo powder dye. Easy to use, Yamato Indigo only needs water; no heating or fermentation is necessary. It dyes natural materials, such as cotton, linen, silk, leather, wood, and washi paper, into a vibrant, beautiful “Japan Blue.”

Yamato Indigo comes in the form of a powder consisting of extracts from indigo plants, synthetic indigo, alkaline agent, and reducing agent. By mixing it with water, it instantly becomes ready to dip and use as a dye.

This indigo dye is the best choice for absolute beginners, workshop teachers, and professional dyers.

10g pack makes 2 to 3 liter vat

Good to dye small items such as napkins and bandanas.

30g pack makes 6 to 10 liter vat

Good to dye medium items such as T-shirts, canvas totes and pillow cases.

*1 liter = 1.05 quart

available in 10g or 30g

Directions are included in the dye packet

Osage Orange gives good results on natural fibers and can be used without a mordant, but the color will be richer, deeper and have greater longevity if the fiber is tanned or mordanted in advance. You can find mordanting directions easily online, my fav is alum.

Osage Orange wood shavings (aprox 4oz per pound of fiber)

Fill your dye pot with warm water from the tap, I put it on its hottest to speed the process. You want it to be roomy enough to swoosh your fiber around and they should be able to fully submerge.

Add the Osage Orange shavings (approx 4oz per pound of fiber) into the dyebath. They will sink as they become saturated and the dyebath heats up.

Raise temperature to 180F (do not go over!!) I use a candy thermometer. Maintain this temp for two hours, cool to room temperature. You can leave it overnight for extra strength.

Strain the shavings. I pour the dye mixture through a cheesecloth over a colander into a big bucket or empty dyepot, be meticulous: Any wood that makes it into the final dyebath can cause splotches on your fabric. dry and save your shavings- they’ll be good for another round! The golden tea thats left is your dyebath.

Rinse your dyepot and put the dyebath back in and add your mordanted, tanned or at least evenly wetted fibers to the dyebath, stirring it around for even saturation.

Raise the temperature to 180°F. Maintain for 2 hours, stirring every 20 minutes or so to encourage an evenness of color.

After 2 hours, allow it to cool to room temperature. Many dyers would leave it overnight- the longer it sits the more intense the color.

Remove the fibers from the dyebath and rinse in lukewarm water until it runs clear.

Hang to dry

Once its dried, you can hand or machine (depends on your fiber) wash with a PH-neutral detergent like Synthrapol

Hang to dry